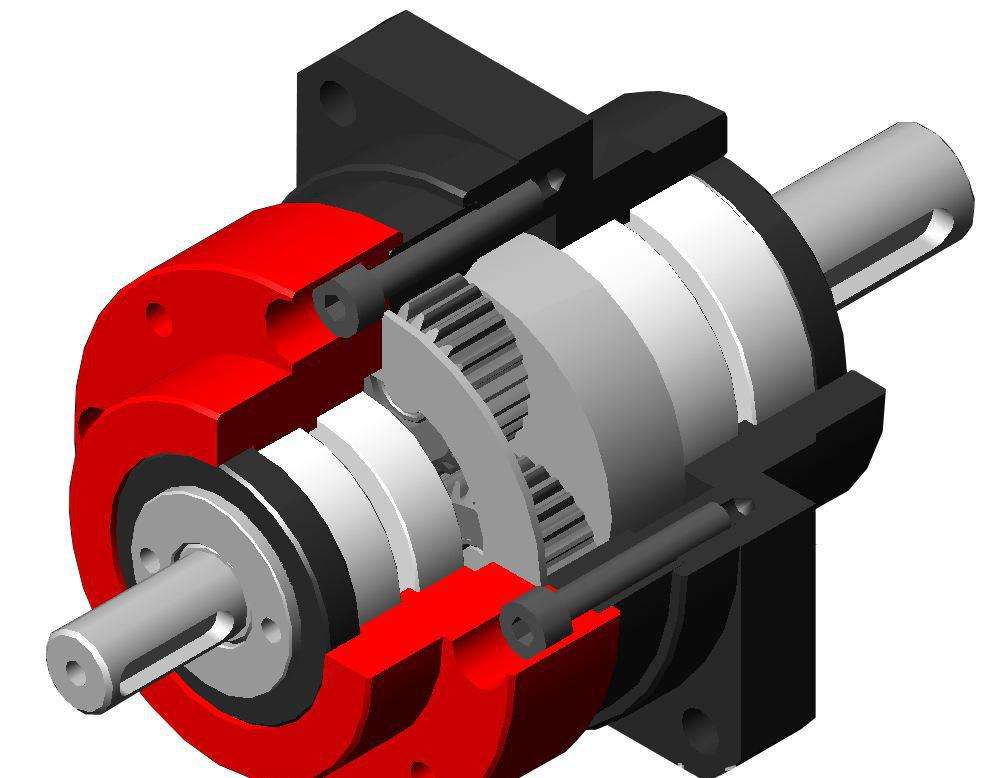

Planetary gearboxes use fewer parts and have simple lubrication. The disassembly and assembly processes of various types of servo gearboxes produced by planetary gearbox manufacturers are basically the same, so disassembly and assembly are easy to maintain. Loosen the screws connecting the output part and the deceleration part in the development zone before lowering the deceleration part; The remaining parts are the motor or end cap input shaft of the input section.

1. Shaft system failure in the deceleration section

Starting from the input section, check whether the motor has any shaft misalignment, small bearing points or large bearing chambers; If there are any, repair or replace the parts, and make the motor run normally with a single machine sound. The rotor shaft rotation runout should be ≤ 0.01mm. Using the rotor rotation center as the reference, measure the perpendicularity between the motor rotor and the flange end face with a dial gauge, which should be ≤ 0.035MM. The concentricity of the stop mouth is ≤ 0.035; The requirements for the input shaft and end cap of the input end are also the same; If they are not qualified, these parts can be aligned on the lathe and installed together, and then inspected for processing.

2. Deceleration section malfunction

The reason why planetary servo gearboxes are reliable, have few faults, and have a long service life is that the main transmission meshing parts are made of high carbon chromium bearing steel with good wear resistance and fatigue resistance, which has good mechanical properties and basically no wear during normal operation. The main failure mode of planetary gearboxes is due to lack of oil or poor lubrication, which causes excessive frictional heat between the center hole and the rotating arm bearing, resulting in annealing, bonding, wear and deformation. The planetary hole and gear are generally not damaged or damaged to a small extent due to lower rotation than them. The force exerted on gears during operation is mainly resistance in the radial direction, while there is no force in the axial direction. Therefore, the two parallel gears and the planetary holes can be used as maintenance benchmarks.

Cheng Shen Precision Machinery (Shanghai) Co., Ltd.

Cheng Shen Precision Machinery (Shanghai) Co., Ltd.