cam indexer is a high-precision mechanical device that converts continuous rotational motion into intermittent motion, with its core being the relative motion relationship between the non-circular cam and the roller driven wheel. Its basic working principle is to drive the internal indexing cam movement through the continuous rotation of the input shaft, so that the output shaft (or turret) rotates intermittently according to the set angle and is accurately positioned at each workstation.

The entire movement process can be divided into two parts: the "movement phase" and the "stop phase". In the motion stage, the roller driven wheel tightly adheres to the cam surface and is pushed by the cam to run. This cam surface presents a non-circular shape, and through a precisely designed curve, the driven wheel is controlled to complete three stages of acceleration, uniform speed, and deceleration, thereby achieving smooth and impact free rotational positioning. The rolling contact between the cam and the follower effectively reduces wear and noise, improving the service life and working stability of the mechanism. At the stopping stage, the roller driven wheel is located in the flat area of the cam surface, and the output shaft is completely stationary, ensuring precise positioning and facilitating assembly, inspection, machining, and other operations.

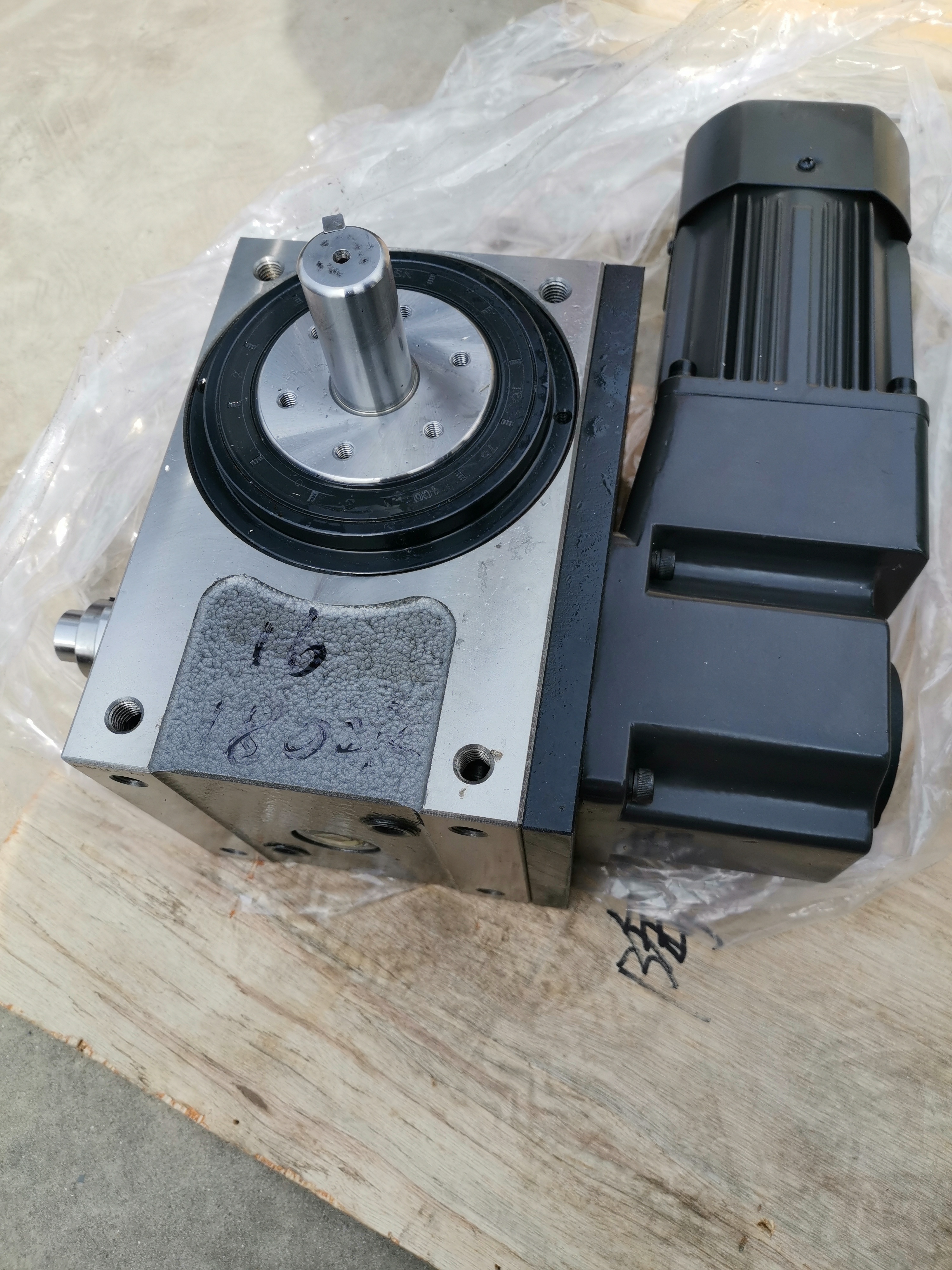

The cam curve of the indexing table is usually designed in the form of a deformed sine curve or a modified conjugate cam curve, based on the required segmentation angle, degree, operating time ratio, and load characteristics. The entire structure is protected by a sealed shell and made of high-strength alloy material, which has the characteristics of high rigidity, high precision, and zero backlash. It is an important foundation for achieving stable and repetitive positioning of automated equipment.

Compared with traditional intermittent mechanisms, the cam indexing rotary table has almost no impact vibration during operation, and the segmentation accuracy can reach ± 15 seconds or even higher. It is suitable for various multi station automation devices in industries such as electronics, packaging, pharmaceuticals, printing, and food. It not only improves the efficiency of equipment operation, but also greatly reduces the frequency of mechanical maintenance and error occurrence. Therefore, the precision cam indexing device is widely regarded as one of the "heart" components in modern automation systems.

Cheng Shen Precision Machinery (Shanghai) Co., Ltd.

Cheng Shen Precision Machinery (Shanghai) Co., Ltd.